Layher Tower

Safety included

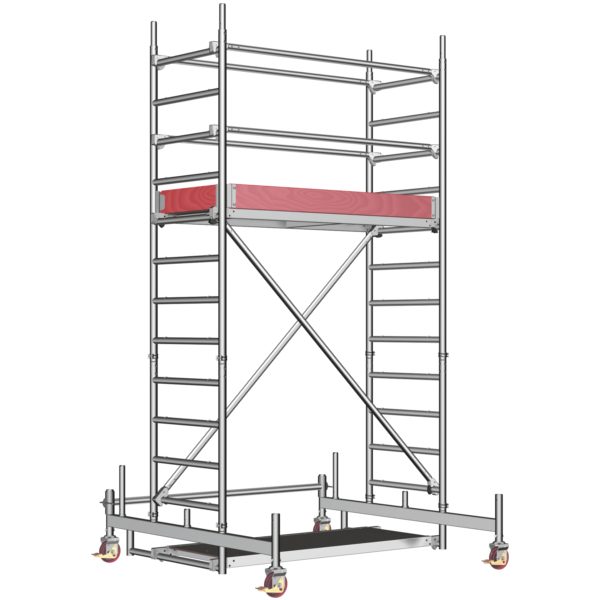

Zifa Tower P2

The \”ready-made tower\” for working at low heights

Area of working platform: 0.75 x 1.80 m

Working height: 7.76 m

Uni Light P2

The practical layher tower for working

in cramped conditions

Area of working platform: 0.75 x 1.80 m

Working height: 9.26 m

Uni Compact P2

The compact scaffold tower

with double-width working surface

Area of working platform: 1.50 x 1.80 m

Working height: 10.38 m

Uni Standard P2

The most flexible rolling tower

for very great heights

Area of working platform: 0.75 x 2.85 m

Working height: 13.38 m

Uni Wide P2

The layher tower for the highest heights with double-width working surface

Area of working platform: 1.50 x 2.85 m

Working height: 13.38 m

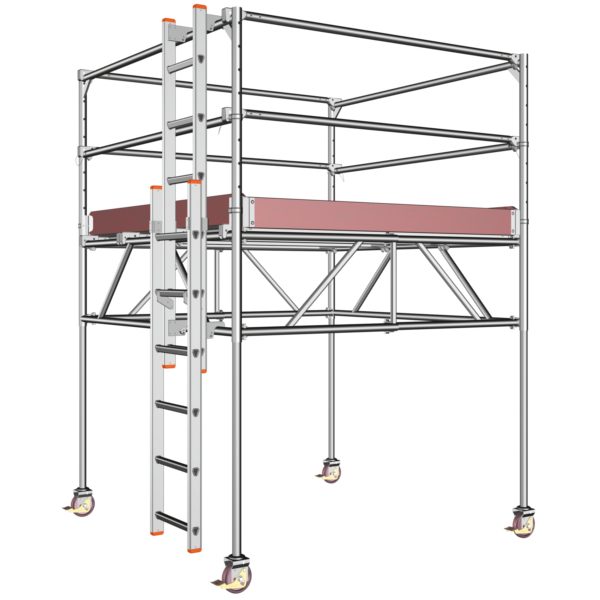

Uni Comfort

The layher tower with

convenient stairway access

Area of working platform: 1.50 x 1.80 m

Working height: 14.20 m

Staro rolling tower

The ready-made layher tower for freedom of movement and a large working area

Area of working platform: 1.95 x 1.95 m

Working height: 3.90 m

Layher tower: Which advantages does it have?

- WHEELS

Sturdy wheels for high manoeuvrability and stable stance during work. Various wheel coatings permit use even on sensitive floor coverings. The steel base plates ensure easy and precise height equalisation while transmitting the loads centrally into the locked wheel. This improves the stability, enabling the user to work efficiently.

- LADDER FRAMES

- GUARDRAILS AND DIAGONAL BRACES WITH SNAP-ON CLAWS

- DECKS

- STABILITY